The first experiment of laser cutting didn't work to plan. I had my pages oriented incorrectly (should be LANDSCAPE 812.8mm TALL, 475.2mm WIDE).

To use the machine, I opened my corel file, made sure everything was rgb red (the corel red), barcode numbers only had a blue outline (no black anywhere!!!), each line was a single line, and hairline thickness. Then grouped it and window selected the image (CNTRL + G)/ File/ Print/ Selection/ Properties: MDF 3mm... this is what I used) ok/ Print.

Then I opened the laser program, made sure it was on my slide, then pressed PLAY BUTTON to print.

Couple of issues with the machine, but I just had to clean up my file.

Unfortunately in my first attempt I had miscalculated the site's contour heights and somehow did not scale them accordingly with my other site objects (ie - the sheds were too large).

14 June 2011

11 June 2011

Laser Cutting the Site Model - Process

The next thing on my weekly 'To Do' list is to laser cut a site model (roughly to the same scale as my bar web 3D prototype).

It was a long and involved process going from Blender, to Revit, to AutoCad, to Corel Draw.

Steps:

1. Cut sections in BLENDER at 3 meter intervals (using 3mm ply sheets). I imported the model into Revit, measured the distance between the cliff and river (was approximately 30 meters) then worked backwards (needed 10 sections cuts horizontally etc.)

The same principle was applied to the story bridge (vertical sections), and my important shed buildings on site.

To cut a section in Blender: join the object all together first (p)/ make a plane/ select the object/ cursor to selection (shift+S)/ and move the plane into the position where I want it cut for a section..... then Scripts/ Object/ Cross Section/ Yes: fill objects...... then export this.... Scripts/ Export/ Autodesk.DXF

2. Import sections into AUTOCAD (open the .dxf file). These are to be scaled up in CAD or REVIT to the size I want cut. I then had 2 options: 1/ keep all of the lines on layer 0 so that they could be changed colour in Corel... or 2/ change the lines to be cut: RED, slightly etched: BLUE, large blocks of text and images: BLACK. (NOTE: COULD ALSO USE GREEN AS GUIDELINES AS THEY DON'T PRINT).

In AUTOCAD I also drew up a mock laser template for the machine and made sure my objects fit on those pages (400mm x 800mm) before saving them as the oldest possible Autocad file (AUTOCAD 2000.dwg).

3. Open the Autocad file in COREL DRAW, checked all lines were hairlines (pen nib tool, select hairline)/ fit all of the puzzle pieces onto my pages (leaving 5mm margins, 390mm x 790mm)/ made sure each piece was code labeled in blue/ then grouped the number to the piece (select both/ Cntrl+G)... then saved it.

It was a long and involved process going from Blender, to Revit, to AutoCad, to Corel Draw.

Steps:

1. Cut sections in BLENDER at 3 meter intervals (using 3mm ply sheets). I imported the model into Revit, measured the distance between the cliff and river (was approximately 30 meters) then worked backwards (needed 10 sections cuts horizontally etc.)

The same principle was applied to the story bridge (vertical sections), and my important shed buildings on site.

To cut a section in Blender: join the object all together first (p)/ make a plane/ select the object/ cursor to selection (shift+S)/ and move the plane into the position where I want it cut for a section..... then Scripts/ Object/ Cross Section/ Yes: fill objects...... then export this.... Scripts/ Export/ Autodesk.DXF

2. Import sections into AUTOCAD (open the .dxf file). These are to be scaled up in CAD or REVIT to the size I want cut. I then had 2 options: 1/ keep all of the lines on layer 0 so that they could be changed colour in Corel... or 2/ change the lines to be cut: RED, slightly etched: BLUE, large blocks of text and images: BLACK. (NOTE: COULD ALSO USE GREEN AS GUIDELINES AS THEY DON'T PRINT).

In AUTOCAD I also drew up a mock laser template for the machine and made sure my objects fit on those pages (400mm x 800mm) before saving them as the oldest possible Autocad file (AUTOCAD 2000.dwg).

3. Open the Autocad file in COREL DRAW, checked all lines were hairlines (pen nib tool, select hairline)/ fit all of the puzzle pieces onto my pages (leaving 5mm margins, 390mm x 790mm)/ made sure each piece was code labeled in blue/ then grouped the number to the piece (select both/ Cntrl+G)... then saved it.

10 June 2011

Hardening the 3D Rapid Prototype

Once the models had been baked and dried slowly in the oven, they had to be hardened with a fixing agent.

The thicker concert shell was fine just apply 1 layer of the glue to (making sure not to go over any area twice or else it smudged). However, considering the web model was a lot finer, it had to be firstly drenched in glue hardener, quickly dried with the cool air gun, then resprayed with a sea salt water base mix to make it more rigid.

The thicker concert shell was fine just apply 1 layer of the glue to (making sure not to go over any area twice or else it smudged). However, considering the web model was a lot finer, it had to be firstly drenched in glue hardener, quickly dried with the cool air gun, then resprayed with a sea salt water base mix to make it more rigid.

2 June 2011

3D Prototype in Oven

Here is the update of the 3D prototypes live from the drying oven! They ran out of hardener but hopefully by next week it'll all be applied and they'll be right for me to take home.

The web worked nowhere near as well as the shell which is ironic considering I applied the same thickness of 5mm to both... yet the web came out at about 2mm?

The shells are great and look really sturdy which I think is a product of it being one plane (I saw many other models similar to my web thrown in the bin as they broke)

The web worked nowhere near as well as the shell which is ironic considering I applied the same thickness of 5mm to both... yet the web came out at about 2mm?

The shells are great and look really sturdy which I think is a product of it being one plane (I saw many other models similar to my web thrown in the bin as they broke)

1 June 2011

3D Models in REVIT, SOLID WORKS, Z PRINT & 3D RAPID PROTOTYPER

This week was a huge experimentation one trying out Revit, Solid Works, Z Print and the 3D rapid prototypes in the industrial workshop.

REVIT

Steps of how to bring blender model into revit and scale it up to be able to cut sections through etc. below:

1 - Bring model into revit (import)

2 - Look on google maps to gauge the scale of the site and measure something (I measured the story bridge was 30m wide).

3 - Back in Revit, draw a ML (model line) on the floor plan at 30 000 (as have set it up in mm)

4 - Scale up the model according to this by: select model/ modify/ scale/ click the 3 following points (1. edge of bridge., 2. other edge of bridge that I want to stretch to the 30 000 mark., 3. point where I want the model scaled up to which is the 30 000 mark).

This made for some interesting sections, but they were cluttered with trees etc.

SOLID WORKS

The workshop informed me that I had to pass the blender file through solid works before it would successfully print in the rapid prototyper (powder)... which didn't turn out to be the case! But I learnt a lot in the process.

I started by fixing up the faces of my imported STL file in Solid works so that it would print the 3D form properly. I spent ages and was told that I wasn't allowed to use the whole cone shape for my stage shell, but had to shell it to waste less powder before sending to print. This defeated me stitching it up in Blender in the first place (!!!!!!) but at least I got to practice my facing skills in Blender so wasn't a waste of time.

The way to thicken the shell in solid works was to 1/ select the outside faces of the shell I wanted to form together (as an outside surface) and then thicken them. I selected feature recognition from the top tool bars/ thicken/ thick outwards 0.05 so that it would print to be 5mm thick. Then save as stl unit in meters.

For the intricate web, I spent hours trying to heal all to close up all the faces but I couldn't get them all healed. Then simon walked in and said I didn't need to do that anyway and could have just copied and pasted the shape straight into Z Print by literally dragging it straight in!

So that was that! And I'll go to pick up my models tomorrow to see if they work. For the record, the lady next to me just modeled up a sketchup model and saved it as 3DS which was perfectly fine to once again COPY and PASTE straight into the Z Print file without converting it at all! This then fills up a box on the screen with all the models to print in the overnight session.

Below is a picture of the 3D rapid prototyper:

The white powder that forms our models looks like this:

REVIT

Steps of how to bring blender model into revit and scale it up to be able to cut sections through etc. below:

1 - Bring model into revit (import)

2 - Look on google maps to gauge the scale of the site and measure something (I measured the story bridge was 30m wide).

3 - Back in Revit, draw a ML (model line) on the floor plan at 30 000 (as have set it up in mm)

4 - Scale up the model according to this by: select model/ modify/ scale/ click the 3 following points (1. edge of bridge., 2. other edge of bridge that I want to stretch to the 30 000 mark., 3. point where I want the model scaled up to which is the 30 000 mark).

This made for some interesting sections, but they were cluttered with trees etc.

SOLID WORKS

The workshop informed me that I had to pass the blender file through solid works before it would successfully print in the rapid prototyper (powder)... which didn't turn out to be the case! But I learnt a lot in the process.

I started by fixing up the faces of my imported STL file in Solid works so that it would print the 3D form properly. I spent ages and was told that I wasn't allowed to use the whole cone shape for my stage shell, but had to shell it to waste less powder before sending to print. This defeated me stitching it up in Blender in the first place (!!!!!!) but at least I got to practice my facing skills in Blender so wasn't a waste of time.

The way to thicken the shell in solid works was to 1/ select the outside faces of the shell I wanted to form together (as an outside surface) and then thicken them. I selected feature recognition from the top tool bars/ thicken/ thick outwards 0.05 so that it would print to be 5mm thick. Then save as stl unit in meters.

For the intricate web, I spent hours trying to heal all to close up all the faces but I couldn't get them all healed. Then simon walked in and said I didn't need to do that anyway and could have just copied and pasted the shape straight into Z Print by literally dragging it straight in!

So that was that! And I'll go to pick up my models tomorrow to see if they work. For the record, the lady next to me just modeled up a sketchup model and saved it as 3DS which was perfectly fine to once again COPY and PASTE straight into the Z Print file without converting it at all! This then fills up a box on the screen with all the models to print in the overnight session.

Below is a picture of the 3D rapid prototyper:

The white powder that forms our models looks like this:

21 May 2011

Option 2 for tidying blender file ready for 3D rapid prototype exporting

As my bar feature structure is more complicated than the previous models, it was best to try and cut the face to prevent a tedious process of stiching it back together at the point where I sliced the figure.

I put the object and a large plane onto layer 3 so as to isolate them (M/ 3rd box/ and use the `~ key to get back the whole scene)... I then moved the plane up to where I wished to cut the shape sectionally. Then I selected the object SHIFT+ the plane/ W/ Difference/delete and you're meant to be left with the cut shape desired.

This appeared to be working well. However when I applied the normals checking process to this object, I noticed it was chaotic with normals and faces as seen below:

I also started to notice gaps in the facade, but was struggling to find the actual vertices to stich it back together as previously done in the first 2 models. I will go and see Simon in the workshop about this next week.

I put the object and a large plane onto layer 3 so as to isolate them (M/ 3rd box/ and use the `~ key to get back the whole scene)... I then moved the plane up to where I wished to cut the shape sectionally. Then I selected the object SHIFT+ the plane/ W/ Difference/delete and you're meant to be left with the cut shape desired.

This appeared to be working well. However when I applied the normals checking process to this object, I noticed it was chaotic with normals and faces as seen below:

I also started to notice gaps in the facade, but was struggling to find the actual vertices to stich it back together as previously done in the first 2 models. I will go and see Simon in the workshop about this next week.

20 May 2011

Converting Blender Model into STL format for 3D rapid prototyping

The first thing that had to be done with my stage model mounds was to stitch their faces up entirely so that I would produce a solid mound for both pieces.

This was done by being in edit mode. Have the magnet icon activated/4 vertices selection button on/ E (extend vertices down to a common flat base distance)/ Z/ CNTRL+hover over vertice I want to pull my vertice down to it's position in the z axis.

This was done for all vertices at the base and then they were stitched together using faces (SHIFT+select up to 4 vertices then F (faces)).

I then had to check that all of the normals were facing outwards so as to be able to be 3D rapid prototyped. This was done in edit mode of the object/ Mesh Tools More/ N size:1.5/ have Draw Normals selected. Be in face selection mode/ right click on the face that has the normals facing inwards/ EDIT button (4 vertices in square)/ Mesh Tools/ Flip Normal. Repeat for all faces like this.

This was done by being in edit mode. Have the magnet icon activated/4 vertices selection button on/ E (extend vertices down to a common flat base distance)/ Z/ CNTRL+hover over vertice I want to pull my vertice down to it's position in the z axis.

This was done for all vertices at the base and then they were stitched together using faces (SHIFT+select up to 4 vertices then F (faces)).

I then had to check that all of the normals were facing outwards so as to be able to be 3D rapid prototyped. This was done in edit mode of the object/ Mesh Tools More/ N size:1.5/ have Draw Normals selected. Be in face selection mode/ right click on the face that has the normals facing inwards/ EDIT button (4 vertices in square)/ Mesh Tools/ Flip Normal. Repeat for all faces like this.

MY FINAL 5 WEEK DEVELOPMENT PLAN (from last week's class)

WEEK 1

Make changes to my model according to Florian's feedback from Assignment 2.

This includes:

Good

• good presentation

• great diagrams

• the process worked well in helping us understand

• good details and understanding of the tectonics

Bad

• the rendered images are too black

• get rid of the fence

• morph a shape over the shed you’ll use for the bar so it ties in with the stage shape

• sound protection for the apartments

WEEK 2

Have a 3D rapid prototype done (modified experiment)

WEEK 3

Have a laser cut prototype done (fine to be the same experiment, just try this technology)

WEEK 4

REVIT documentation completed

WEEK 5

A week to do final panels, fly-throughs, print 1 day earlier than due, and powerpoint in Indesign (animations must work!!!).

Make changes to my model according to Florian's feedback from Assignment 2.

This includes:

Good

• good presentation

• great diagrams

• the process worked well in helping us understand

• good details and understanding of the tectonics

Bad

• the rendered images are too black

• get rid of the fence

• morph a shape over the shed you’ll use for the bar so it ties in with the stage shape

• sound protection for the apartments

WEEK 2

Have a 3D rapid prototype done (modified experiment)

WEEK 3

Have a laser cut prototype done (fine to be the same experiment, just try this technology)

WEEK 4

REVIT documentation completed

WEEK 5

A week to do final panels, fly-throughs, print 1 day earlier than due, and powerpoint in Indesign (animations must work!!!).

19 May 2011

Shed object experiments - fluid simulation of water #5

While the structure fitted in with the strong geometric triangular form of the story bridge's cross bracing above, when considered in context of the site, and particularly the grass mounds intended for landscaping of the concert venue's seating and stage/sound built form, I decided to apply a modifier to achieve a more organic form.

This looked terrific and could be a really interesting structure for patrons to sit under inside the shed as well as an indication of its presence externally. Perhaps people could crawl up into that area to sit under with friends as another indoors option to sitting outside. The flood could be timber and they could sit up against cushions and see outside through glazing. The bar could be to the left of the building in this image.

This looked terrific and could be a really interesting structure for patrons to sit under inside the shed as well as an indication of its presence externally. Perhaps people could crawl up into that area to sit under with friends as another indoors option to sitting outside. The flood could be timber and they could sit up against cushions and see outside through glazing. The bar could be to the left of the building in this image.

Shed object experiments - fluid simulation of water #4

As previously stated the form needed to be moved out of the arch way and scaled down so as to respectfully fit into the site.

I then applied a plastic mesh like effect we learnt in class by selecting the water form object/ Z (wireframe) / scripts/ mesh/ solid wireframe/ ok (and maintained the default thickness as when increased it to 2 it took over the the whole site).

I then applied a plastic mesh like effect we learnt in class by selecting the water form object/ Z (wireframe) / scripts/ mesh/ solid wireframe/ ok (and maintained the default thickness as when increased it to 2 it took over the the whole site).

Shed object experiments - fluid simulation of water #3

The fluid was captured and frozen in a mesh from by selecting it, then ALT+C (delete the existing form). This can then be tabbed into for edit mode to alter it's structural form.

Shed object experiments - fluid simulation of water #2

In stills the video was caught in the following format before modifiers were added. The problem here is that the shape blocks the critical vista point from the path above between the bridge's arch and so this doesn't fit appropriately with the site.

Image below taken from mural walkway at top of cliff under the bridge which is frequented by many pedestrians and bike traffic hourly.

Image below taken from mural walkway at top of cliff under the bridge which is frequented by many pedestrians and bike traffic hourly.

Shed object experiments - fluid simulation of water #1

The first fluid simulation (nothing changed changed) to come up with a roof shape that is morphing over the sheds. This is to represent rain falling down onto the site in its subtropical climatic site of brisbane and to see how this interacts with the iconic story bridge above.

Adjusting project in accordance with crit feedback

In accordance with the crit feedback, I have altered my model to adjust lamp settings (changed to sun and reduced the luminance via energy rating value below 1). Also changed the background to black and deleted the fence lines through editing faces. What I discovered is that I actually had two models inserted into my composition and this was causing issues with lighting of my stage in the rendered images. So I selected the top model/ tabbed into edit mode/ W/ remove doubles.

I also noticed a few issues with the ground level being deleted. After no avail with face stitching, I created a base plane to work with for simulations.

I also noticed a few issues with the ground level being deleted. After no avail with face stitching, I created a base plane to work with for simulations.

12 May 2011

Feedback from Florian about assignment 2

Great experiments and has come up nicely for this point. Remove the fence between the venue and the existing heritage buildings however and landscape this more effectively. Also maybe use another experiment to interact with the existing sheds if I am proposing to use these as they don't look like a unified space. Perhaps drape a cloth off the shed and this creates an undercover walkway or morph a shape into the building...

Sunday afternoon jazz sessions at UNDERGROUNbD

Here's a snippet of the vibe at one of the weekly Sunday afternoon jazz sessions proposed for the UNDERGROUNbD, Howard Smith Wharves.

3 May 2011

Cloth concept development

The cloth was moved and I experimented with utilising its submerged form as land contours for the outdoor space.

Experiment 2 applied modifiers subsurf but this created too many hard angles that would retain debris.

So I utilised this form again but placed the same force fields in context as before so see whether I may be able to use the hairs for something in the structure of landscaping.

The cloth was rotated and trimmed to allow water to pass through and will be anchor bolted to the cliff for extra support.

Once trimmed (hold B + MMB) and delete faces and vertices, the result left a terrific form of cross bracing, which in line with my readings is on the diagonal to the oncoming river flood current, which provides extra lateral strength for the structure.

Experiment 3 CLOTH

The successful simulation has generated an interesting end form that I will now utilise. To get there I rotated my plane X90/ y:4/ Z:0

Experiment 2 CLOTH as water in context

The cloth is meant to represent the tidal/water associated forces on the site as demonstrated in this diagram below:

Instead of applying two clothes from each direction to represent L/ the flood coming downstream and R/ a tsunami coming in from sea, I have just created one horizontal plane and will see how it reacts with the existing form in a less literal way.

The settings for this animation were similar to the cloth on cube experiment, but I also added a Y:2.5 value in gravity settings of the cloth (plane object) soas to emulate water moving in those directions.

The cloth didn't drape though and just sinks through the river bed.

Instead of applying two clothes from each direction to represent L/ the flood coming downstream and R/ a tsunami coming in from sea, I have just created one horizontal plane and will see how it reacts with the existing form in a less literal way.

The settings for this animation were similar to the cloth on cube experiment, but I also added a Y:2.5 value in gravity settings of the cloth (plane object) soas to emulate water moving in those directions.

The cloth didn't drape though and just sinks through the river bed.

Experiments with cloth to then be applied to folie

I wanted to experiment with cloth as wasn't enjoying the forms created from fluid simulation. Perhaps I'll use that later to determine zones with my outdoor area...

So I did a simple test on a cube to practice the effect: create a plane in top view above the cube. Select plane/ cloth z:-3 (slows the animation). Select Cube/ Fields Collision tab/ collision. Select plane again/ edit (TAB)/w/subdivide multi/ 25 cuts. TAB out to object mode/ BAKE.

So I did a simple test on a cube to practice the effect: create a plane in top view above the cube. Select plane/ cloth z:-3 (slows the animation). Select Cube/ Fields Collision tab/ collision. Select plane again/ edit (TAB)/w/subdivide multi/ 25 cuts. TAB out to object mode/ BAKE.

Something always good to think about - Nature

While not directly a requirement of the brief, it is always good to think about effective structures that are in place in nature and how they work in terms of whole system management, form, structure, etc. That the shape is a result of a complex network behind it...

2 May 2011

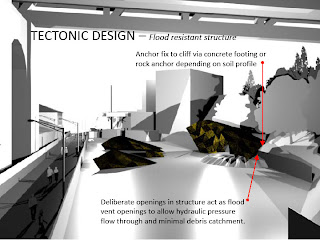

Tectonic theory to consider when generating form

Detailed notes from Design for Flooding: Architecture, landscape and urban design for resilience to climate change (2010) are now considered during the design phase, as part of the cross pollination process between technological modeling and considered design.

As we know flooding is a natural part of Brisbane's hydrological system. Aspects to consider in my design include zone separation, raising the building above minimum flood level codes, designing for severe wind and wave impacts, and choosing materials that are waterproof and resistant to water damage.

When considering my building envelope I wish to design it to be capable of minimising penetration of wind, rain and debris. Structurally this will mean reinforcing my walls and using sealants to reduce seepage of floodwater through walls and wall penetrations. I could also consider installing pumps and back up power generation to control interior water levels if I have an enclosed space close to flood level.

Tectonically, cross bracing would be beneficial in my structure as it provides lateral windhydrodynamic wave and tsunami resistance as well as support to the foundation system. While this may potentially trap debri, I will address this by placing bracing parallel to the primary direction of the brisbane river's downstream flow.

In my membrane I will specify close nail spacing and hold down anchors connected to the foundation with corrosion resistant bolts. The foundation could possibly be grade beams and a pier combination for extra strength so that I don't have to rely on the soils beneath for vertical support considering the whole site goes under in the flood.

Forces to consider are diagrammed well in the image below:

It is also a good idea to consider flood vent openings that will automatically open during a flood to prevent the external wall failing and let the wave's pressure flow through the building. Note this is to be below 250mm above FFL high.

Flood damage resistant materials that I could specify include:

- Glazed brick, concrete block, glass block or stone (With waterproof mortar or grout)

- Steel trusses, beams, panels or hardware

- Naturally decay-resistant lumber, or marine-grade plywood

- Clay, concrete, rubber or steel tiles (with chemical set or waterproof adhesives)

- Cement board or cement fiberboard

- Metal doors, cabinets and window frames with drainage weeps

- Mastic, silicone or polyurethane formed-in-place flooring

- Sprayed polyurethane foam or closed-cell plastic foam insulation

- PVC trim, molding, rail, deck and sheets, impervious to moisture and insects

- Water resistant glue

- Polyester epoxy paint (Mildew resistant paint contains toxic ingredients and should not be used indoors)

- Hot dipped galvonised stainless steel screws and nails

Before going onto the next stage of my form generation, I wanted to be aware of what materials and tectonic options were available to me, and to also practically consider what factors I should be thinking about in terms of resistant architecture.

Watson, D., Adams, M (2010). Design for flooding: Architecture, landscape, and urban design for resilience to climate change. Retrieved from http://reader.eblib.com.au.ezp01.library.qut.edu.au/%28S%281lbjizf2045eal1jugj5ox4e%29%29/Reader.aspx?p=624403&o=96&u=b2PwBbP4uOU4QuPXRPVSPA%3d%3d&t=1302588905&h=87AF126B15D716BA206CE162A36A1BE334D48F71&s=4104035&ut=245&pg=1&r=img&c=-1&pat=n#

As we know flooding is a natural part of Brisbane's hydrological system. Aspects to consider in my design include zone separation, raising the building above minimum flood level codes, designing for severe wind and wave impacts, and choosing materials that are waterproof and resistant to water damage.

When considering my building envelope I wish to design it to be capable of minimising penetration of wind, rain and debris. Structurally this will mean reinforcing my walls and using sealants to reduce seepage of floodwater through walls and wall penetrations. I could also consider installing pumps and back up power generation to control interior water levels if I have an enclosed space close to flood level.

Tectonically, cross bracing would be beneficial in my structure as it provides lateral windhydrodynamic wave and tsunami resistance as well as support to the foundation system. While this may potentially trap debri, I will address this by placing bracing parallel to the primary direction of the brisbane river's downstream flow.

In my membrane I will specify close nail spacing and hold down anchors connected to the foundation with corrosion resistant bolts. The foundation could possibly be grade beams and a pier combination for extra strength so that I don't have to rely on the soils beneath for vertical support considering the whole site goes under in the flood.

Forces to consider are diagrammed well in the image below:

It is also a good idea to consider flood vent openings that will automatically open during a flood to prevent the external wall failing and let the wave's pressure flow through the building. Note this is to be below 250mm above FFL high.

Flood damage resistant materials that I could specify include:

- Glazed brick, concrete block, glass block or stone (With waterproof mortar or grout)

- Steel trusses, beams, panels or hardware

- Naturally decay-resistant lumber, or marine-grade plywood

- Clay, concrete, rubber or steel tiles (with chemical set or waterproof adhesives)

- Cement board or cement fiberboard

- Metal doors, cabinets and window frames with drainage weeps

- Mastic, silicone or polyurethane formed-in-place flooring

- Sprayed polyurethane foam or closed-cell plastic foam insulation

- PVC trim, molding, rail, deck and sheets, impervious to moisture and insects

- Water resistant glue

- Polyester epoxy paint (Mildew resistant paint contains toxic ingredients and should not be used indoors)

- Hot dipped galvonised stainless steel screws and nails

Before going onto the next stage of my form generation, I wanted to be aware of what materials and tectonic options were available to me, and to also practically consider what factors I should be thinking about in terms of resistant architecture.

Watson, D., Adams, M (2010). Design for flooding: Architecture, landscape, and urban design for resilience to climate change. Retrieved from http://reader.eblib.com.au.ezp01.library.qut.edu.au/%28S%281lbjizf2045eal1jugj5ox4e%29%29/Reader.aspx?p=624403&o=96&u=b2PwBbP4uOU4QuPXRPVSPA%3d%3d&t=1302588905&h=87AF126B15D716BA206CE162A36A1BE334D48F71&s=4104035&ut=245&pg=1&r=img&c=-1&pat=n#

Subscribe to:

Comments (Atom)